decided to upgrade the protein feeder. Only have a 300 lb now so going to upgrade to 500-750 timed protein feeder. Suggestions on to buy a dedicated timed protein feeder or buy one and use the hammer?

Announcement

Collapse

No announcement yet.

DIY timed protein feeder

Collapse

X

-

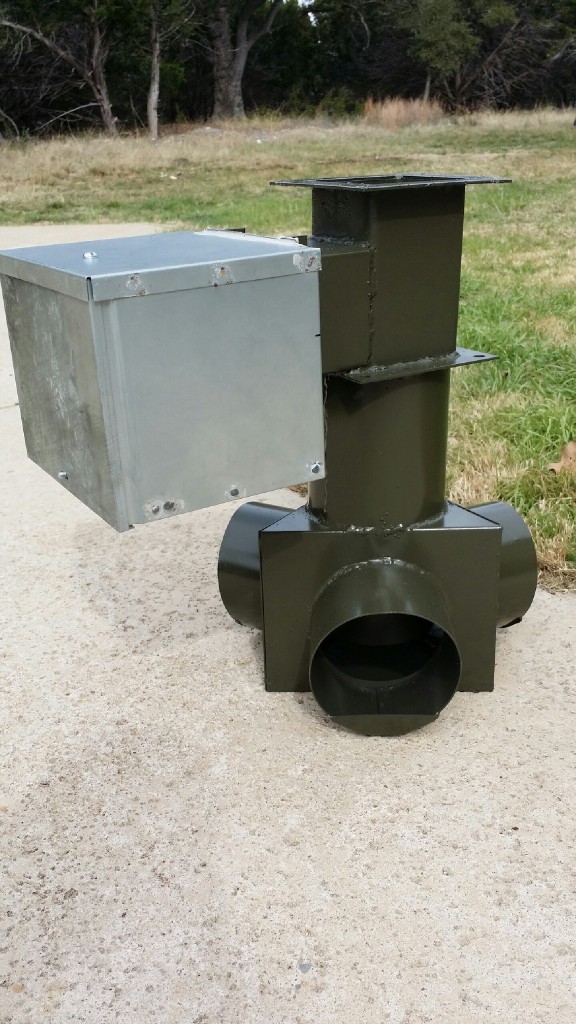

Originally posted by timoub007 View PostHere are some pictures of how you can attach a Hammer feeding system to an All Seasons 2k Evolution protein feeder.

The silver parts are called unistrut, and besides metal shops you can find it at Home Depot. There are captive nuts designed for the slotted rails or you could probably get by with common nuts and bolts if you wanted to spend more time fiddling with the connections. There are 90 degree angle brackets holding the pieces of unistrut together. I drilled two holes in the top of the mechanism box and ran bolts up into the captive nuts in the piece of unistrut on top of the box.

ASF Evolution 2k pf Hammer conversion https://imgur.com/a/BXvAKVM

Thank you Mike for shipping me just the mechanism, box and timer and for answering my questions to get this done. I just installed it last weekend and will report back about it after some time has gone by. I have little doubt that it will work as expected.

Tim

Oh wow. You got the Hammer system moving the big shut off plate. That is genius if it works.

I have seen the tubes cut off but never done this way.

Please let me know how it works. I would love to convert my 3K ASF.

Comment

-

In my last reply I mentioned that I would provide an update on how my modified ASF is working with the Hammer unit moving the big shut off slide.

It took a little bit of tweaking and a couple of attempts but I believe that I have it setup perfectly now. The way that the slide gate is constructed in the 2k pf allows for pellets to get trapped in the track that the gate slides in. These pieces of protein were causing the slide to bind and bottom out before the actuator had finished it's stroke. When this happens it would either try to bend or break stuff at attachment points or it would pop the fuse.

To combat this I installed a few small pieces of sheet metal inside the feeder that shrinks the opening slightly. This keeps the pellets away from the tracks on each side and allows me to adjust the actuator so that it does not have to close the slide all the way against the end track, it just closes enough to move past the sheet metal I added.

These changes have the 2k working well!!!

After I got the Hammer installed on the 2k I tackled installing it on my older 1k ASF pf with the 4 round feed tubes. I approached the installation the same as I did on the 2k but it took a little more tweaking to get the unistrut positioned correctly and to hold well since all of the surfaces are round.

The other thing I had to tweak is the stopping point of the actuator stroke and thus how far in the slide moves. This adjustment is actually how I figured out how to get the 2k fixed and running well. You see on the 1k the square slide that stops flow on the round pipe has to go past the end to be fully closed. It is also bigger than the pipe diameter so the tracks that it rides in are not exposed to the protein pellets. When I first got it installed on the 1k, the open position of the actuator was actually just barely opening the slide and no feed was being dropped.

Anyway enough words I'm sure you guys want pictures. Here are some showing both installs discussed in this post.

ASF 2k pf internal modifications and 1k pf Hammer installation https://imgur.com/a/C0T6cga

Tim

Comment

-

Originally posted by timoub007 View PostIn my last reply I mentioned that I would provide an update on how my modified ASF is working with the Hammer unit moving the big shut off slide.

It took a little bit of tweaking and a couple of attempts but I believe that I have it setup perfectly now. The way that the slide gate is constructed in the 2k pf allows for pellets to get trapped in the track that the gate slides in. These pieces of protein were causing the slide to bind and bottom out before the actuator had finished it's stroke. When this happens it would either try to bend or break stuff at attachment points or it would pop the fuse.

To combat this I installed a few small pieces of sheet metal inside the feeder that shrinks the opening slightly. This keeps the pellets away from the tracks on each side and allows me to adjust the actuator so that it does not have to close the slide all the way against the end track, it just closes enough to move past the sheet metal I added.

These changes have the 2k working well!!!

After I got the Hammer installed on the 2k I tackled installing it on my older 1k ASF pf with the 4 round feed tubes. I approached the installation the same as I did on the 2k but it took a little more tweaking to get the unistrut positioned correctly and to hold well since all of the surfaces are round.

The other thing I had to tweak is the stopping point of the actuator stroke and thus how far in the slide moves. This adjustment is actually how I figured out how to get the 2k fixed and running well. You see on the 1k the square slide that stops flow on the round pipe has to go past the end to be fully closed. It is also bigger than the pipe diameter so the tracks that it rides in are not exposed to the protein pellets. When I first got it installed on the 1k, the open position of the actuator was actually just barely opening the slide and no feed was being dropped.

Anyway enough words I'm sure you guys want pictures. Here are some showing both installs discussed in this post.

ASF 2k pf internal modifications and 1k pf Hammer installation https://imgur.com/a/C0T6cga

Tim

Good idea on the internal metal. Looks like you got it working well.

Comment

Comment