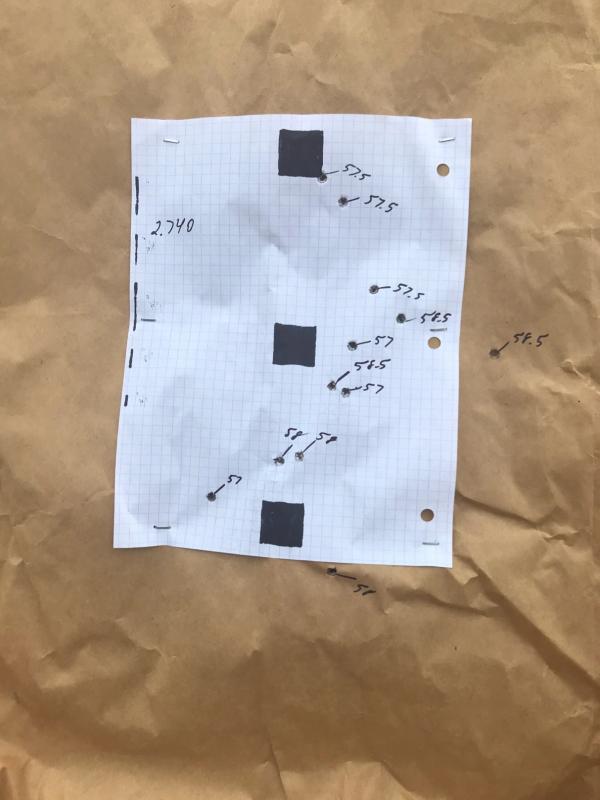

Need help figuring a group out. This is an apr 1:10 twist 24” bartlein build. I get this consistent group at 300 yards. 2 will be close then one goes wild by about 4-5”. At 100 it’s not as drastic but still 1”, and gets extreme at 300. Roughly 1-2 minutes between each series. This grouping is very consistent and deviation on them all are between 10-15 FPS. Shooting 110 accubonds and have tried h4831sc, retumbo, imr 4831 and they’ve all been very similar. Hornady brass is neck sized and brass has been loaded 3-5 times. I have ordered 100 new nosler brass should come in soon. Needing some input as this is driving me nuts. I load for several guns and they’re fine. I have tried playing with multiple depths, bullets and powders. Scope is fine everything is torqued properly. This is a perfect example. Started at 57, 57.5, 58, 58.5 gr each is marked. 58.5 sucked.

Announcement

Collapse

No announcement yet.

Load development help

Collapse

X

-

Looks like seating depth or neck tension to me. I just turned necks on 100 pieces of Hornady 6.5 PRC brass and some of the necks didn't clean all the way up when taking .002! Not telling you you need to turn necks, but that much variation will cause havoc with tension. Since you have access to at least 300, I'd start over doing a ladder to identify the nodes, then go back to seating depth to fine tune. I'd be glad to help walk you through some things to try. Just call the shop and ask for me.

Robert

817-284-0034

Comment

-

Originally posted by Stick1 View PostLooks like seating depth or neck tension to me. I just turned necks on 100 pieces of Hornady 6.5 PRC brass and some of the necks didn't clean all the way up when taking .002! Not telling you you need to turn necks, but that much variation will cause havoc with tension. Since you have access to at least 300, I'd start over doing a ladder to identify the nodes, then go back to seating depth to fine tune. I'd be glad to help walk you through some things to try. Just call the shop and ask for me.

Robert

817-284-0034

What would you recommend for seating depth? I will re-do ladder test with new brass.

Comment

-

Let me qualify this by stating that this is NOT my pic. Just found it on a quick search and am only posting it because it is an AWESOME example of how a ladder test can easily show your accuracy nodes and save a lot of wasted components and barrel life. You can clearly see how a node exists between 30.5 - 30.7. This method works for me 90% of the time.

Comment

Comment