This is the latest design for a feeder that I have built. It may be a bit tall for some but I have never had a coon or squirrel get to my feeder unit to do any damage.

Material:

2 Joints of 1" schedule 40 black pipe with plain ends

1 Joint of 1 1/4" schedule 40 Black pipe with plain ends

Some 1" x 1" x 1/4" angle iron

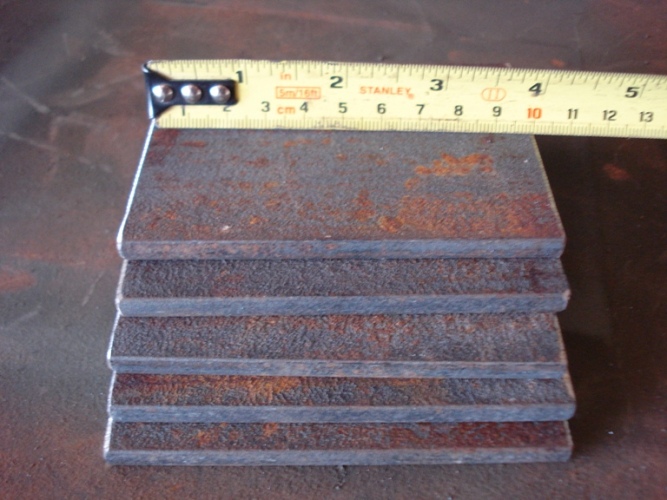

Some 4" x 1/4" flat iron

1 8.5" circle of 1/4" flat plate

Some 1 1/4" x 1 1/4" x 3/16" angle iron

Winch

Cable

Pulley

Eye bolt 1/2"

Connecting Link

Shackle

Cut the 1" pipes into 7' and 6' sections (3 of each)

Cut the 1 1/4" pipe in 4' and 3' sections (3 of each)

Cut the angle iron into 18" pieces (3 each)

Cut the flat iron into 4" (5 each) and 5" (3 each)

Cut a 20 degree angle on one end of the 4' sections of the 1 1/4" pipe

Weld those to the 8.5" x 1/4" top plate

Add the 1 1/4" angle iron braces

Drill a 1/2" hole in the middle of the plate and install the pulley assembly

Material:

2 Joints of 1" schedule 40 black pipe with plain ends

1 Joint of 1 1/4" schedule 40 Black pipe with plain ends

Some 1" x 1" x 1/4" angle iron

Some 4" x 1/4" flat iron

1 8.5" circle of 1/4" flat plate

Some 1 1/4" x 1 1/4" x 3/16" angle iron

Winch

Cable

Pulley

Eye bolt 1/2"

Connecting Link

Shackle

Cut the 1" pipes into 7' and 6' sections (3 of each)

Cut the 1 1/4" pipe in 4' and 3' sections (3 of each)

Cut the angle iron into 18" pieces (3 each)

Cut the flat iron into 4" (5 each) and 5" (3 each)

Cut a 20 degree angle on one end of the 4' sections of the 1 1/4" pipe

Weld those to the 8.5" x 1/4" top plate

Add the 1 1/4" angle iron braces

Drill a 1/2" hole in the middle of the plate and install the pulley assembly

). After I switched to the winch up style, I never even got a pic of them trying to climb the legs. I don't think the realized where the corn was coming from since my barrel was winched up so high.

). After I switched to the winch up style, I never even got a pic of them trying to climb the legs. I don't think the realized where the corn was coming from since my barrel was winched up so high.

Comment