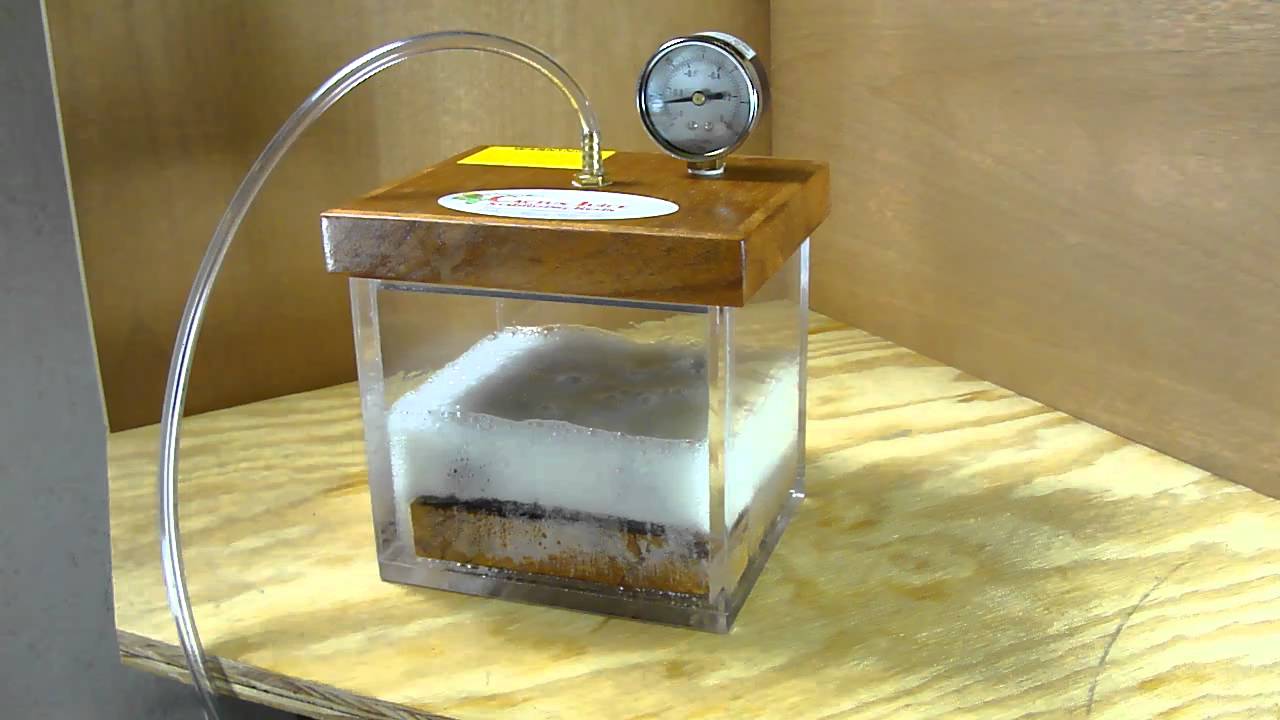

A friend of mine (Dave, pbuh) had a bunch of 1/2" plexiglass he said I could use, so I made a vacuum chamber. I just finished it. This is me holding it up by the lid so you can see that it's holding a vacuum.

I'm going to put some rests on the bottom to lift the wood up a little. I'll probably also add a gauge at some point.

I'm using Gold's Gym 6' stretch band (same stuff as Theraband) for a gasket. I originally got it to make slingshots, but it works great for a gasket because it's wide enough that I can just cut out the middle of it, and there's no seam around the edges.

Originally, I used some silicone glue to glue it to the lid, but it wouldn't hold a vacuum. So I pealed that off, cleaned it up, and put another one on there without gluing it. It's just sitting between the lid and the rim. It seems to work!

I bought one of those round vacuum chambers made out of a pyrex dish on ebay a while back, but I don't like it because with its shape, it's not as easy to put square pieces of wood in it. And it's not very tall, so you have to be really careful when you initially put on the vacuum and all those bubbles rise up. With this square plexiglass one, I can get more wood in it at a time, and it's taller, so I don't have to worry so much about the bubbles getting up in the valves and pump and stuff.

I found a guy on craigslist who makes grills, and he had some scrap pieces of expanded metal. I'm going to use that to make a weight like Curtis Seebeck uses to keep the wood submerged in the Cactus Juice.

<--happy me

<--happy me

I'm going to put some rests on the bottom to lift the wood up a little. I'll probably also add a gauge at some point.

I'm using Gold's Gym 6' stretch band (same stuff as Theraband) for a gasket. I originally got it to make slingshots, but it works great for a gasket because it's wide enough that I can just cut out the middle of it, and there's no seam around the edges.

Originally, I used some silicone glue to glue it to the lid, but it wouldn't hold a vacuum. So I pealed that off, cleaned it up, and put another one on there without gluing it. It's just sitting between the lid and the rim. It seems to work!

I bought one of those round vacuum chambers made out of a pyrex dish on ebay a while back, but I don't like it because with its shape, it's not as easy to put square pieces of wood in it. And it's not very tall, so you have to be really careful when you initially put on the vacuum and all those bubbles rise up. With this square plexiglass one, I can get more wood in it at a time, and it's taller, so I don't have to worry so much about the bubbles getting up in the valves and pump and stuff.

I found a guy on craigslist who makes grills, and he had some scrap pieces of expanded metal. I'm going to use that to make a weight like Curtis Seebeck uses to keep the wood submerged in the Cactus Juice.

<--happy me

<--happy me

Comment